The encoder market is witnessing remarkable growth, driven by increasing automation across industries and the need for precision in various applications. The global encoder market size attained a value of nearly USD 2.42 billion in 2023. The market is further expected to grow in the forecast period of 2024-2032 at a CAGR of 8%, reaching nearly USD 4.83 billion by 2032. Encoders, vital components in industrial machinery, robotics, and other automation technologies, are playing an increasingly critical role in modern production processes.

In this blog post, we will delve into a detailed analysis of the encoder market, exploring its types, technologies, and end-use industries. We’ll also provide insights into regional growth trends, market dynamics, and the competitive landscape to give you a comprehensive understanding of where this market is headed in the coming years.

Market Outlook and Forecast (2024-2032)

The global encoder market is on a steady growth trajectory, thanks to the increasing adoption of Industry 4.0 technologies, rising demand for precision engineering, and the need for enhanced process automation across various industries. Encoders are essential for measuring motion, speed, and position, making them indispensable in modern manufacturing.

The market’s expansion is being fueled by advancements in automation and robotics in sectors like automotive, electronics, and pharmaceuticals. Industries are increasingly adopting encoders to improve accuracy, reduce errors, and optimize production, thus driving the market’s robust growth. However, high initial costs and integration complexities are potential challenges that could affect market adoption, particularly in price-sensitive regions.

Market Segmentation

By Type

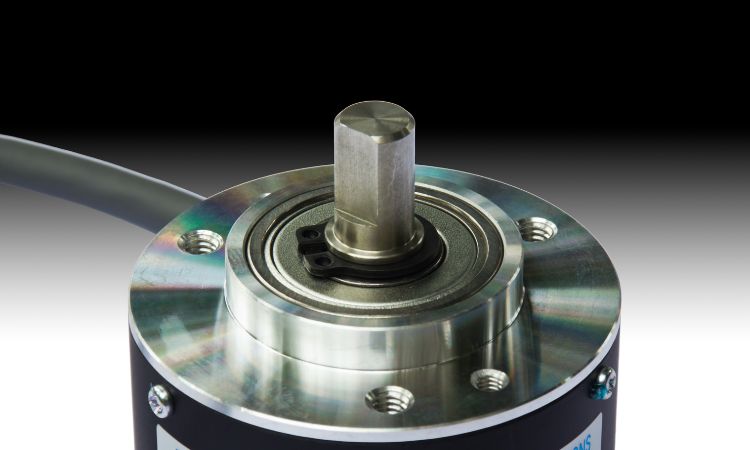

- Rotary Encoder Rotary encoders are among the most widely used types of encoders. These devices measure rotational motion and are extensively applied in robotics, industrial machines, and automotive systems. Rotary encoders are valued for their ability to provide precise feedback regarding position, speed, and direction. Their use in industrial automation and robotics is expected to rise significantly during the forecast period.

- Linear Encoder Linear encoders measure linear motion, making them ideal for applications requiring precise distance or position feedback. These encoders find applications in CNC machines, factory automation, and textile machinery. With the growing demand for high-precision equipment in industries like manufacturing and electronics, linear encoders are projected to experience substantial growth.

By Technology

- Optical Encoders Optical encoders dominate the market due to their high precision and accuracy. These encoders use light to detect position changes and are commonly used in applications that require precise motion control, such as robotics, medical devices, and industrial automation. Optical encoders are expected to remain the preferred choice in high-precision environments.

- Magnetic Encoders Magnetic encoders, which operate by detecting changes in a magnetic field, are gaining traction due to their durability in harsh environments. They are less susceptible to dirt and debris, making them suitable for outdoor and industrial settings where contaminants might interfere with optical encoders.

- Photoelectric Encoders Photoelectric encoders use light-sensitive elements to detect position and movement. They are commonly used in environments requiring a fast response time, such as in packaging machinery and automation systems. Although not as popular as optical encoders, they have a specific market due to their speed and efficiency.

- Others There are several other types of encoder technologies, including capacitive and inductive encoders, which cater to niche applications. These alternatives offer specific advantages, such as lower costs or better performance in certain environments, making them useful for specialized applications.

By End Use

- Automotive The automotive industry relies heavily on encoders for applications such as controlling braking systems, managing steering mechanisms, and ensuring smooth automated vehicle operations. With the rise of electric and autonomous vehicles, the demand for encoders in the automotive sector is expected to grow significantly.

- Electronics The electronics industry uses encoders to manufacture semiconductors, smartphones, and other consumer electronics. Precision and automation are critical in electronics manufacturing, and encoders play a key role in enhancing productivity and ensuring quality control.

- Textile The textile industry has embraced automation to improve efficiency and product quality. Encoders are used in textile machinery to measure tension, speed, and positioning, contributing to more efficient operations and reduced material waste.

- Printing Machinery Encoders are crucial in the printing industry, helping ensure accurate registration and alignment in high-speed printing processes. They also help in controlling the speed and positioning of paper, contributing to the production of high-quality prints.

- Industrial Encoders are integral to various industrial applications, from factory automation to process control. The industrial sector is expected to remain a significant end-use market for encoders due to ongoing advancements in automation and robotics.

- Pharmaceuticals In the pharmaceutical industry, precision is crucial, particularly in the production and packaging of drugs. Encoders help maintain accuracy in machinery used for drug manufacturing, filling, and packaging.

- Others Other sectors, including aerospace, defense, and healthcare, are also adopting encoders to ensure precision in their operations. These industries are increasingly incorporating automation and robotics, which rely on accurate feedback systems provided by encoders.

Regional Analysis

North America

North America remains a key market for encoders, driven by its advanced manufacturing industries and the widespread adoption of automation technologies. The region is expected to see steady growth, particularly in the automotive and electronics sectors.

Europe

Europe is another significant market, with strong demand from the automotive and industrial sectors. The region’s emphasis on Industry 4.0 and smart factories is expected to fuel the adoption of encoders, especially in Germany, France, and the UK.

Asia-Pacific

Asia-Pacific is anticipated to experience the fastest growth in the encoder market. Countries like China, Japan, and South Korea are leading this surge, driven by their growing industrial sectors, increasing demand for consumer electronics, and the booming automotive industry.

Latin America and Middle East & Africa

These regions are emerging markets for encoders, with potential growth driven by increasing investments in industrial automation and the automotive industry. However, the market is still relatively small compared to North America, Europe, and Asia-Pacific.

Market Dynamics

Market Drivers

- Growing demand for automation and precision across various industries

- Advancements in industrial robotics and smart manufacturing

- Rising adoption of electric and autonomous vehicles

Market Restraints

- High initial cost of encoders and integration complexity

- Competition from alternative technologies

Opportunities

- Technological advancements in encoder technology

- Growing demand in emerging markets such as Asia-Pacific and Latin America

Competitive Landscape

The global encoder market is highly competitive, with key players focusing on innovation and technological advancements to maintain their market positions. Major companies include:

- HEIDENHAIN

- Renishaw

- Rockwell Automation

- Honeywell International

- Baumer Group

These companies are investing heavily in research and development to produce more efficient and advanced encoder systems to meet the growing demands of automation across industries.